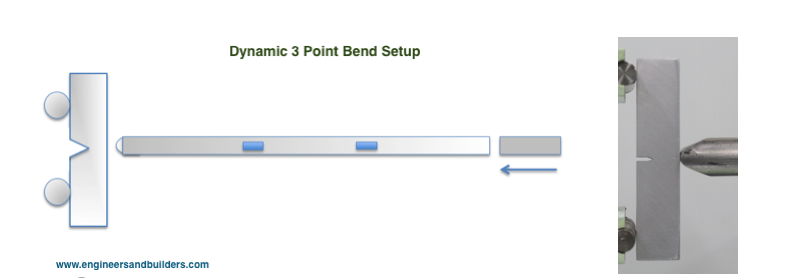

In comparison of static fracture toughness, characterisation in terms of dynamic fracture toughness is much more involved. Our 3 point bend experimental rig comfortably handles the inertial effects [1] for Wide variety of specimens in terms of material and geometry. Transient loading is applied and calibrated using two / three point measurement technique on a single instrumented bar. It also allows accurate observation of crack initiation by easy integration of techniques like strain gauges, wire fracture gauges [2-3] and high speed photography [4-5].

When you buy a dynamic 3 point bend setup from us you also get a high speed data acquisition (>10 MHz/Channel) along with the customized Matlab based software for the analysis. Some of the hardware and data acquisition options offered by us can be seen below:

| Bar Strength: 100 to 1400 MPa | Bar Diameter: 12 to 25mm | Bar Type: Solid | Fixture: Adjustable |

| Acquisition: 4 Analog & 4 Digital | Sampling Rate: 1 to 10 Mhz/Ch | Trigger: Internal and External | Analysis software: SHPB 2.0C |

For any information or a customisation of our 3 point bend setup for your need, you can contact us through our contact us page.

References:

[1] Kalthoff J.F , Winkler, S. and Beinert J, The influence of dynamic effects in impact testing. International Journal of Fracture,13, 528–531, 1977.

[2] Rittel D, Maigre H and Bui H D, A new method for dynamic fracture toughness testing. Scripta Metallurgica et Materialia, 26, 1593–1598, 1992.

[3] Bacon C, Färm J, Lataillade J L, Dynamic fracture toughness determined from load-point displacement. Exp. Mech., 34, 217-223, 1994.

[4] Dally W J, Dynamic photo-elastic studies of fracture. Exp. Mech., 19, 349-361, 1979.

[5] Sutton M A, Orteu J and Schreier H, Image Correlation for Shape, Motion and Deformation Measurements. Springer, 2009.