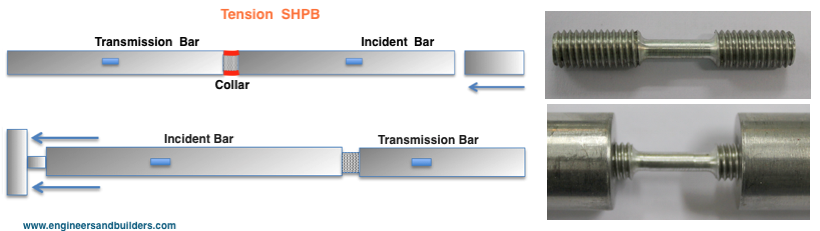

A complete material characterization involves evaluating dynamic constitutive behavior under both compression and tension loading conditions. But unlike dynamic compression, conducting dynamic tension experiment is not as straight forward. This is evident by very less attention given to dynamic tension studies and few research publications in the literature. In 1960 Harding and Wood [1] modified design by Kolsky and built a setup suitable for dynamic tensile testing. Later it was further modified by Harding and Welsh [2] to test fiber reinforced composite specimens. Since then many researchers [3 – 8] have tested other designs and fixtures, but even today dynamic tensile tests are considered complicated in comparison to their compression counterparts.

Tension SHPB by E&B

Our customized TSHPB or Tensile SHPB offers a great amount of freedom to evaluate wide range of materials under excellent stress or force equilibrium. It allow users to swap different kind of bars with ease, and to adjust projectile launch pressure and its velocity. When you buy TSHPB from us you also get a high speed data acquisition (>10 MHz/Channel) along with the customized Matlab based software for the analysis. Some of the hardware and data acquisition options offered by us can be seen below:

| Bar Strength: 100 to 1400 MPa | Bar Diameter: 12 to 50mm | Bar Type: Solid and Hollow | Strain Rate: 100 to 5000 |

| Acquisition: 4 Analog & 4 Digital | Sampling Rate: 1 to 10 Mhz/Ch | Trigger: Internal and External | Analysis software: SHPB 2.0B |

For any information or a customisation of TSHPB for your need, you can contact us through our contact us page.

References:

[1] Harding J, Wood EO, Campbell JD, Tensile testing of materials at impact rates of strain. J Mech Eng Sci 2(2): 88–96, 1960.

[2] Harding J and Welsh L M, A tensile testing technique for fiber-reinforced composites at impact rates of strain, J. Mater. Sci. 18 1810–26, 1983.

[3] Nicholas T, Tensile testing of materials at high rates of strain, Exp Mech 21(5), 177–185, 1981.

[4] Staab G H and Gilat A, A direct-tension split Hopkinson bar for high-strain-rate testing, Exp. Mech. 31 232–5, 1991.

[5] Yuan J M, Shim V P W, Tensile response of ductile titanium at moderately high strain rates, Int. J. of Solids and Structures, 39, 213-224, 2002.

[6] Cao K, Wang Y and Wang Yu, Effects of strain rate and temperature on the tension behavior of polycarbonate, Material and Design, 38, 53-58, 2012.

[7] Sasso M, Newaz G and Amodio D, Material characterization at high strain rate by Hopkinson bar tests and finite element optimization, Material Science and Engineering A, 487, 289-300, 2008.

[8] Song B, Antoun B R, Connelly K, Korellis J and Lu W, Improved Kolsky tension bar for tensile characterization of materials, Measurement Science and Technology, 22, 045704, 2011.

[9] Jian Z X, Long Yu and Huang F, Application of split Hopkinson tension bar to the study of dynamic fracture properties of materials, Acta Mech., 28(2) 424-431, 2012.